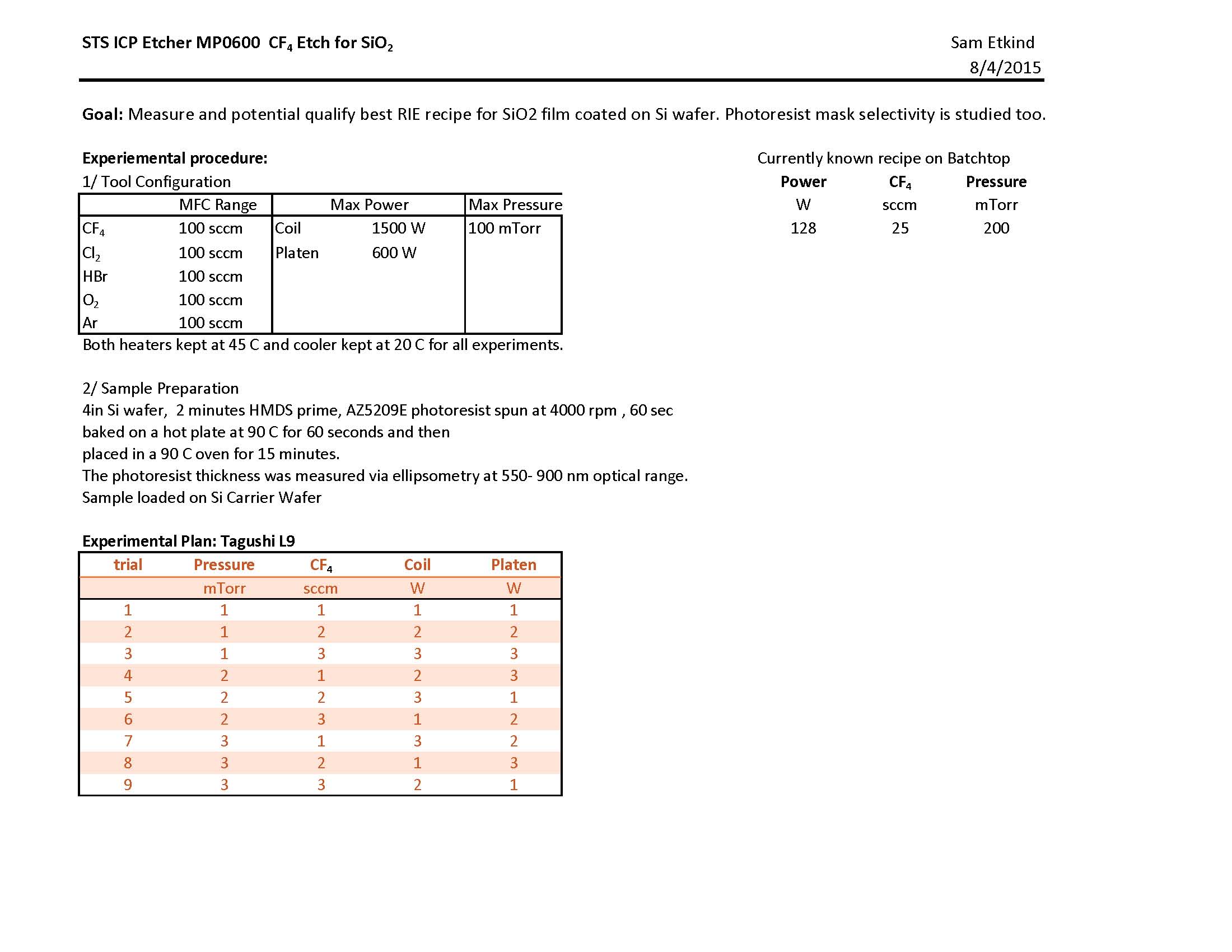

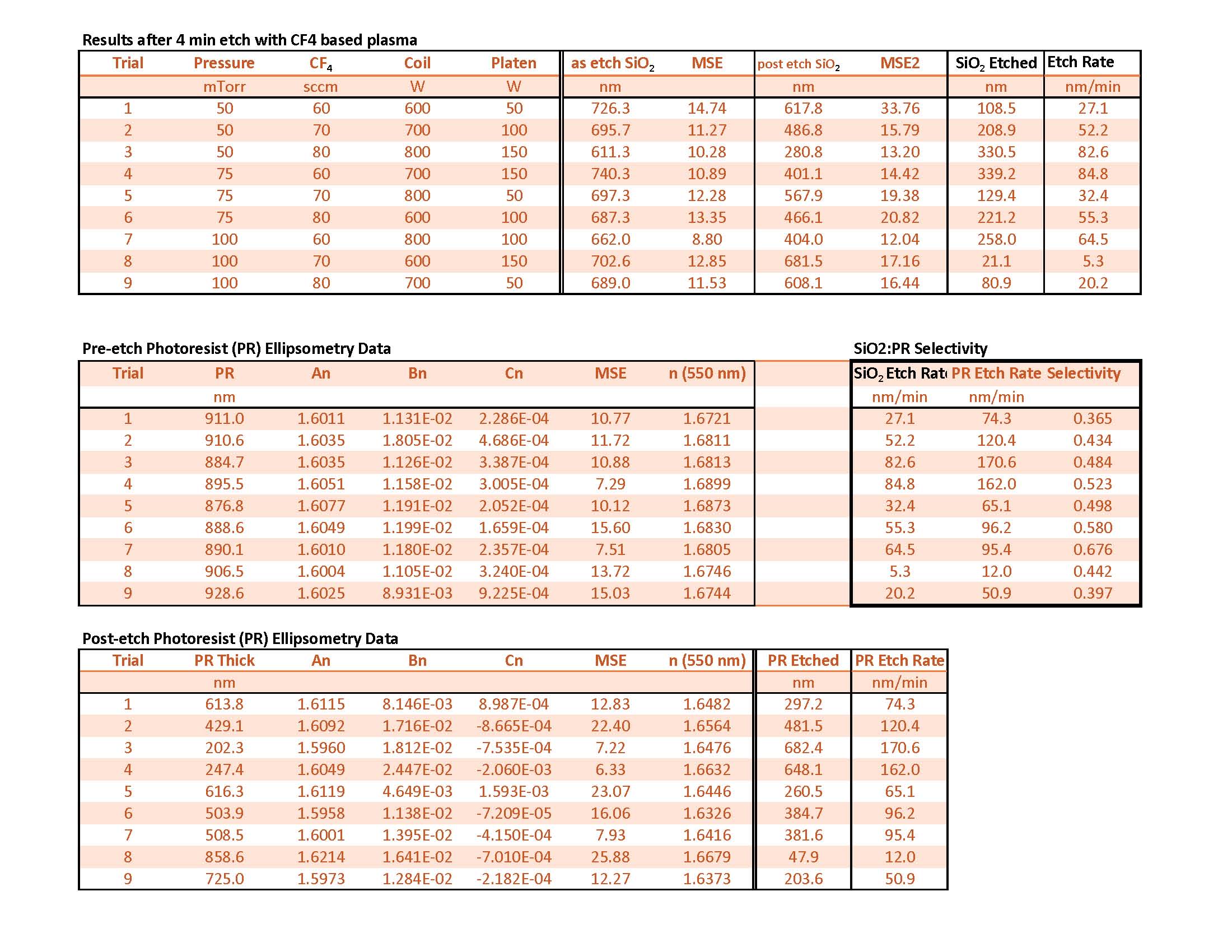

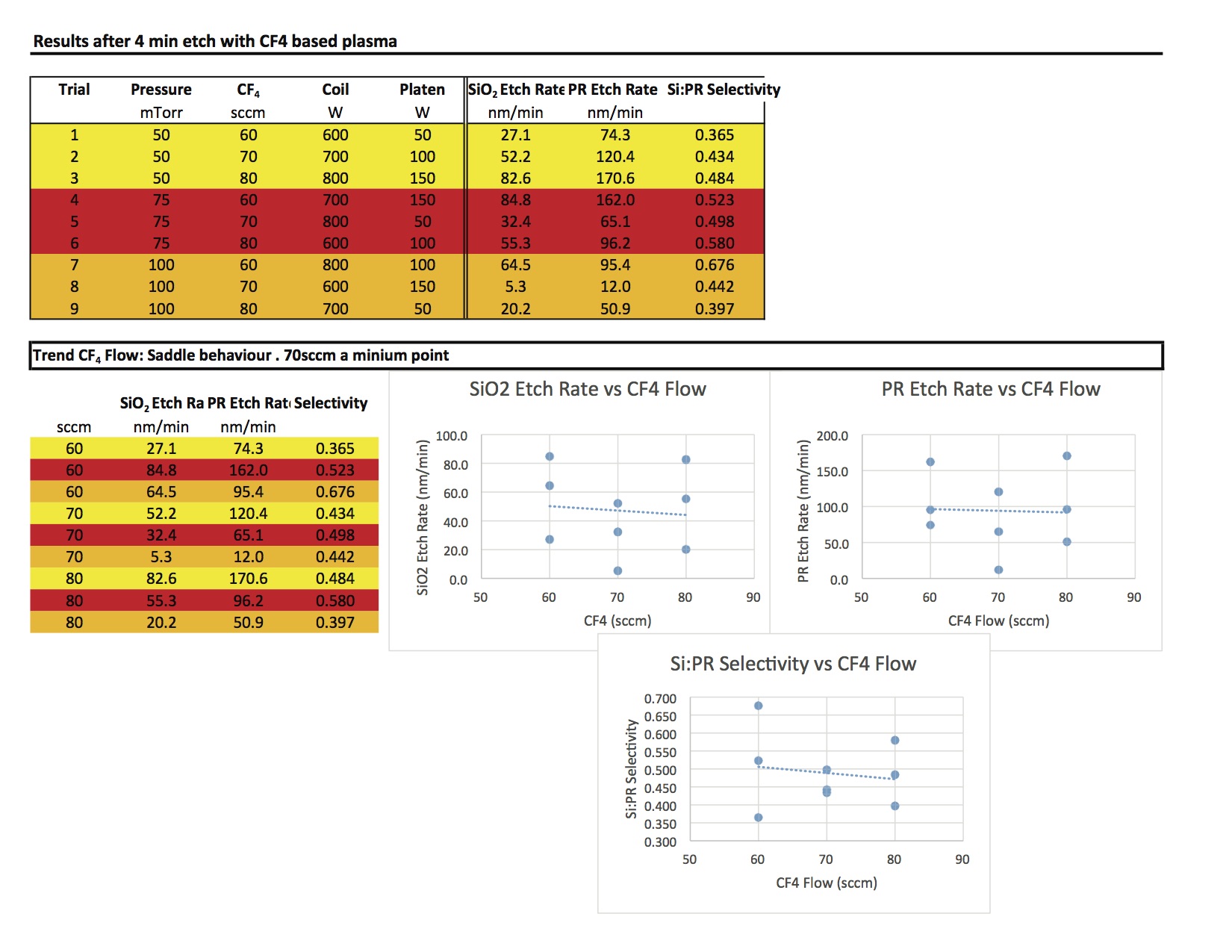

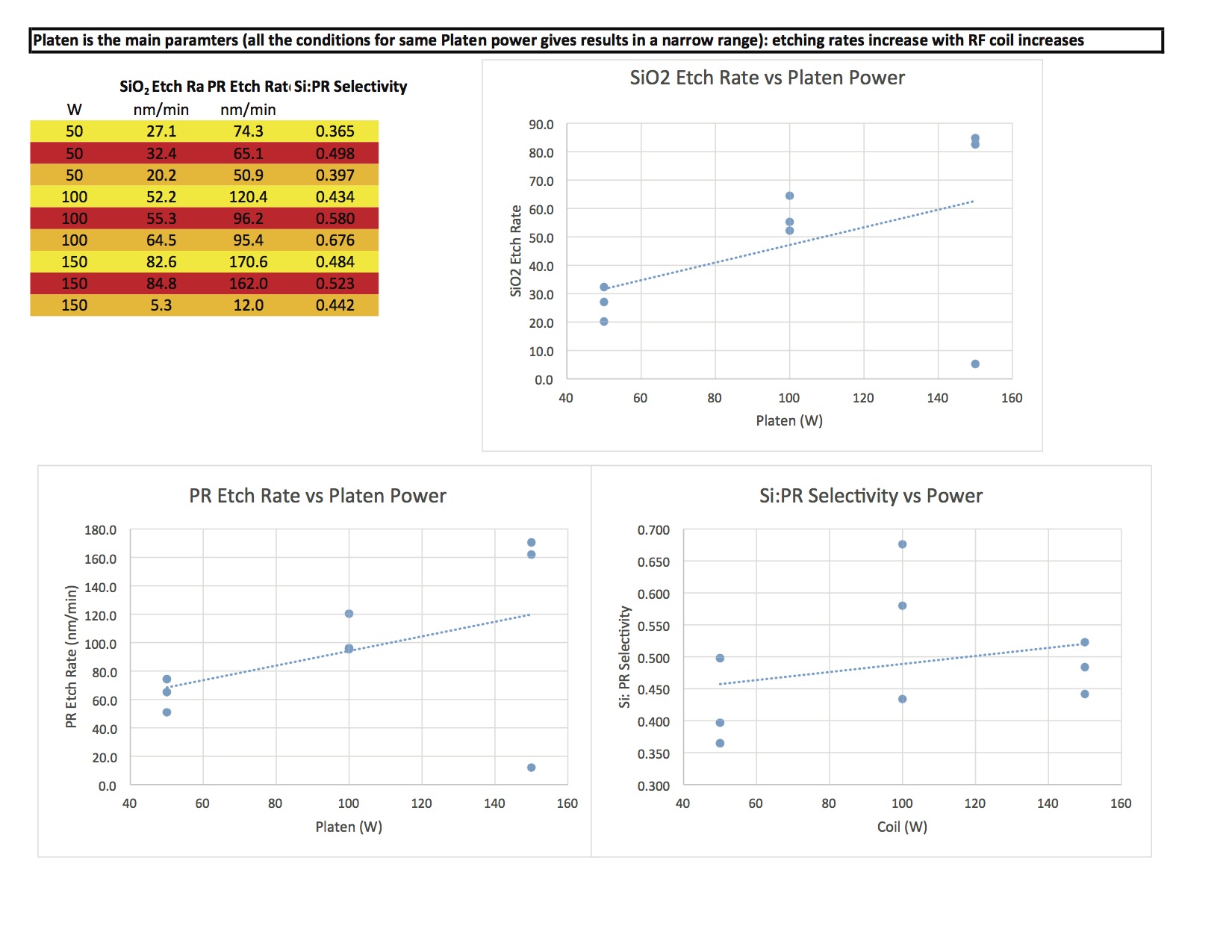

<p>This etch system is characterized with high plasma density, low operating pressure, high etch rate, excellent etch uniformity and low energy ion damage. ICP Etcher is equipped with Platen and Coil generators. Platen Generator typical value is about 1200W. Coil Generator typical value is 600W. He backside cooling Single wafer manual loadlock up to 8" wafer Optimize SiO2 etch recipe at 82nm/min (PR selectivity 0.5): Platen 150W Coil:600W CF4=60-80sccm Pressure: 75mTorr</p>

1.) Log on to recipe using the LabAcess Terminal.

2.) Go to alarms and click Clear All Exceptions

3.) Click Manual and then click Transport Module

4.) Click Vent to bring to chamber to atmosphere.

5.) Load sample, close lid, and click Load to pump down the Transport Module

6.) Once the Transport Module has been pumped, select the gray substrate on the diagram and then select the emtpy slot in the carousel (Process Module). Substrate transfer should now read: From: Carousel Slot 1 now read: From: Carousel Slot 1

7.) Click Start under substrate transfer to transfer the substrate to the Process Module.

8.) To edit a recipe, click Recipe and look for the correct recipe under Process Module.

9.) Click the ⊞ to the left of the recipe to view the steps

Note: Do no edit any parameter except time unless this is your recipe. Violations will be noted.

10.) Click Standard Material Process to edit your process parameters. Time is edited under the

General tab. Other parameters can be viewed under other tabs.

11.) Click Apply to save all changes.

12.) Click Manual and then click Process Module (ICP1)

13.) Go to the Processing tab and select your recipe and click Start.

14.) Once done, return to the Transport Module tab and select the substrate in the chamber and then select the empty slot in the carousel. Click Start to transfer your substrate.

15.) Click Vent and remove your sample.

16.) If finished, click Pump. Otherwise, return to step 3.

To Run an O2 Clean:

Note: An O2 clean should be run for 10-15min before every run, and then run for 1 minute for every 10 minutes of etching. There does not have to be a sample in the chamber during an O2 clean, and the carousel can be loaded and vented during the clean.

1.) Go to the Recipe tab and find O2 Etch_clean chamber

2.) Click on Standard material process and edit the time appropriately. Click Apply to save the changes.

3.) Click on Manual, then Process Module (ICP1) and then Processing.

4.) Find the O2 Etch_clean chamber recipe and click Start

Parameters:

O2 flow

90 sccm

Pressure

20 mTorr

coil (power)

800 W

Platen

100 W

5.) After an O2 plasma treatment, an etch can be run.

Once finished with your recipes, record the appropriate information in the log book.